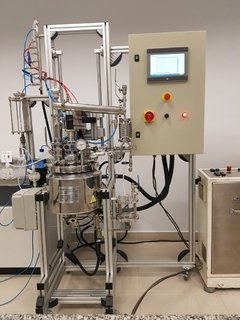

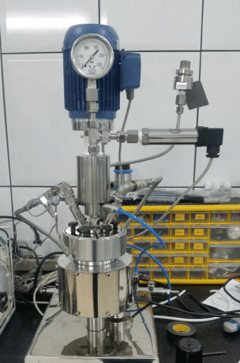

LBR - High Pressure Reactors ( tailor-made )

LBR Series - High Pressure Ballast - Reactor Series LBR - 100 A 200 - RTA Series - 100 A 2000 Capacities 100 to 2000 cc Working Pressure (PMT) -1.0 / + 140.0 bar (2000 psi) Working Pressure (PMTA) -1.2 / + 168.0 bar (2400 psi) Test Pressure (PT) 210.0 bar (3000 psi) Working Temperature 300.0º C Heating Power 0.5 / 2.0 KW Magnetic Barrier Shaker Shield Safety Device Rupture Disc Inert Gas Tube / Fisherman Yes Connections Two Stainless Steel Analog Pressure Gauge Yes Thermocouple Reading and Temperature Control Yes

- Construction material -

Inox 316L, Alloy, Monel, Inconel, Hastelloy, Titanium and so on. Synthetic Description: Vertical cylindrical vase with removable flanged cover, with safety clasp, flat bottoms with straight bottom and movable head. Gaskets Available: Viton FKM fluorado® Kalrez FFKM perfluoroelastomer® Teflon® tetrafluoroethylene polymer PTFE Grafoil® flexible graphite FG Viton®, Kalrez®, Teflon® are registered trademarks of DuPont Grafoil® is a registered trademark of UCAR Carbon Co. Inc. - Heating and Cooling - The heating is obtained by a heating system built in block. bipartite of aluminum, by means of the electrical resistances type cartridges easily replaceable. The cooling is performed in the same block, through perforated channels, through the circulation of cooling fluid. Because it is bi-parti- cular, it allows total withdrawal from the body. The system is insulated by a fibro-ceramic removable thermal blanket protected by fiberglass fabric.

Optional: For operation in qualified area explosion-proof it is recommended to use the super-thermostatic bath of thermal fluid, through the circulation in external jacket. Installed in protected area.

- Reflux -

Two Types of Reflux Systems:

1) Composed of a vertical tubular capacitor connected to the phase separating vessel.

2) Direct Reflux: Tubular capacitor at the top of the reactor.

- Construction material -