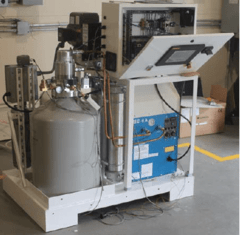

NL84 - Nitrogen Liquefier (40-50 lpd)

-

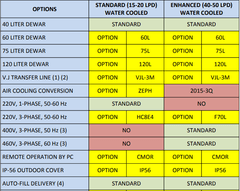

NL84-F: 40-50 liters per day 200-400 VCA, 50-60Hz, trifásico (1) - Enhanced Production

-

FEATURES:

- PLC and Touch Screen Controls

- Zero Installation Effort

- Auto-Delivery for Tool Dewars

- Built-In Diagnostics and Safety Many Optional Configurations .

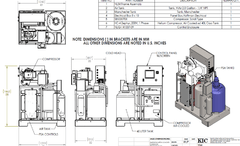

NL84 DETAILED PRODUCT SPECIFICATIONS

- NL84-F Enhanced Production: 40-50 lpd 200 or 400 VAC, 50-60Hz, 3-phase (1)

- Arrangement

- A single integrated assembly is available with several options as described within this brochure. The standard offering is water cooled with a 40 liter dewar.

- Automatic Controls

- PLC and Touch Screen Controls provide fully automatic operation AUTO-START feature for when power returns Digital display of internal and external tank and ALARMS Electronic level gauge for automatic cycling operation Dewar set points (start-stop) can be controlled by customer Password protected functions for user to control access Touch screen push button of LN2 delivery valve Automatic control and display of dewar pressure settings Purity venting for clean start-up of GN2 Calendar and daily operation timing for ON-OFF operation Self diagnostics on every start-up EMO Button for safety Built-in AUTO- DELIVERY of LN2 for external Dewar iPad or Remote PC monitoring and operation are optional 40-50 lpd 200 or 400 VAC, 50-60Hz, 3-phase (1)

- Warranty A three-year warranty on all electronic and electrical components. Lifetime support on software and instrument calibrations.

- Standards This is a CE marked product that meets Health and Safety Standards set forth in the Machinery Directive on machinery safety, 98/37/EC and the International Standards: BS EN ISO 12100-1:2003, BS EN ISO 12100-2:2003, BS EN 294:1992, BS EN 349:1998, BS EN ISO 13850:2006, BS EN 60204-1:1998, BS EN 1050:1997. SEMI S2 Compliance and Certification are Pending (FY2015-3Q)

- Shipping All equipment is cleaned, bagged, and packed in reusable heattreated wooden crates having an international crate shippers compliance standard. This allows for OEM to receive, integrate the NL84, then re-ship to the final destination.

- Performance and Quality Every NL84 is tested at KIC and must pass all Q/C inspections and performance testing prior to being released for delivery. Customers are invited to witness final inspection during the week-long performance and functionality testing procedure.

- Long Life and Reliability Cold head is maintained every 13,000 hours. Helium compressor interval is 30,000 hours. Service and parts are available world-wide.

DESCRIPTION OF AVAILABLE OPTIONS

- 60L The standard 40 liter dewar can be replaced by a larger 60 liter type which allows for the Vacuum Jacketed line option. The liquefier will be 50 mm wider and longer in order to accept this option.

- 75L A taller version of the 40 liter tank allows for more LN2 storage. Similar to the 40 liter standard model, transfer VJ lines are not possible with this option.

- 120L A taller version of the 60L holding 120 liters is available with the same benefits.

- VJL-3M An optional ultra-flexible all Stainless Steel transfer line with a permanent vacuum insulation is available having a length of 3 meters and terminated with a manual unjacketed cryogenic valve. This is the preferred method to feed LN2 to bio storage units. Up to two lines can be installed in each liquefier. The standard electric valve remains so that customer has the ability to AUTO-FILL a third device. The 60 or 120 liter dewars must be ordered for this option.

- ZEPH The Standard model can be configured with air cooling instead of the standard offering of water cooling. This will allow the NL84 to operate in an environment

- HC8E4 Three-phase models are available for higher power efficiencies F70L Higher Current at lower voltages are possible with this option.

- CMOR Using a customer supplied IP Address, the liquefier (and the customers satellite tank) can be remotely monitored and operated from any PC with access. An iPad can also be used for this function, and can be ordered separately. IP56 An enclosure with an IP-56 Ingress rating is available where equipment is outdoors. There are temperature limitations that apply. Consult with KIC before selecting this option. Add 200 mm to all dimensions for this option.

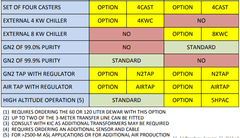

- 4CAST The NL84 is designed to be moved by pallet jacks and forklifts as a permanent installation is usually desired. With the optional caster set (4) the liquefier can be moved by hand. The casters add 300 mm to the height and arrive loose.

- 4KWC A separate chiller is available to remove heat from the water cooled Standard Model where 4kW of heat is removed. It is recommended that chiller be installed outdoors.

- 8KWC A separate chiller is available to remove heat from the water cooled Enhanced d Model where 8kW of heat is removed. It is recommended that chiller be installed outdoors.

- N2TAP A separate regulator provides 2-4 bar GN2 for a separate application.

- AIRTAP A separate regulator provides 6-8 bar Compressed Air.

- 5HPAC A higher capacity 5HP scroll air compressor can be provided for when the Enhanced model is operating above 2500 meters above sea level.