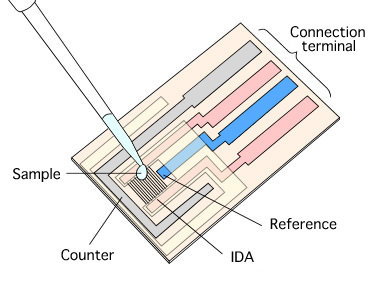

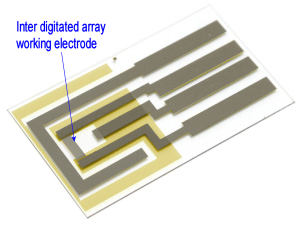

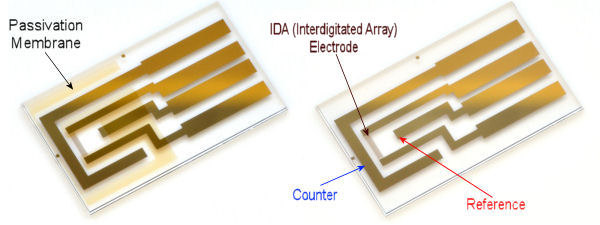

Interdigitated Array (IDA) electrode is an electrode developed for electrochemical measurements to be performed in a very small quantity of the sample. IDA electrode could be applied for the detection and reaction analysis of the compounds in a small quantity of the sample. IDA electrode is a microelectrode pattern fabricated by using the lithography technology. The Electrodes are composed of 65 pairs. In each one of the pair has a function of the oxidation and reduction electrodes.

|

Features・High sensitivity CV measurement

|

|

|

Application example・HPLC measurement electrode

|

|

IDA Electrode is a pair of band electrode combined and meshes with each other as a generator electrode and collector electrode, therefore it is possible to make an electrochemical redox cycle upon the electrode as showed in figure.

By occurring the redox cycle on electrode increasing electrolysis current to raise measurement sensitivity. In experiment using common electrodes to analyze a small quantity of sample solution, the sample will consumed and exhausted due to electrolysis. However using this Interdigitated array electrode, the oxidation-reduction reaction occur repeatedly so the sample solution will not exhausted.

|

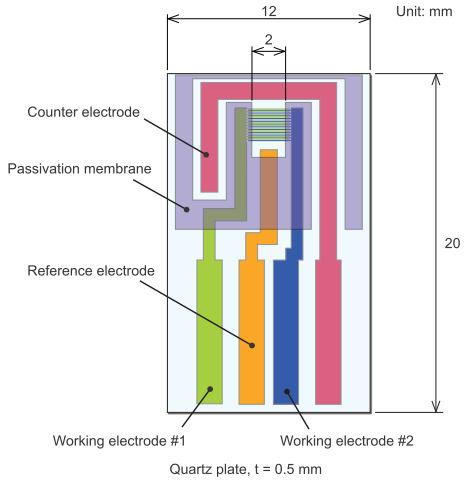

Substrate Dimension | |

| Width | 12.0±0.1 mm | |

| Length | 20.0±0.1 mm | |

| Thickness | 0.5 mm | |

| Electrode Thickness | ||

| Au | 90 nm | |

| Pt | ||

| C | 1.2 ± 0.1 μm | |

| ITO | 100 nm | |

| Adhesive layer - Passivation membrane thickness | ||

| Ti | approximately 10 nm (∗only for Au and Pt) |

|

| Passivation membrane | about 1 μm | |

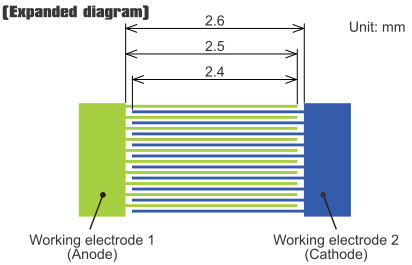

| Catalog No. | Description | Width (µm) | Interval (µm) | Length (mm) | Number of feet (pairs) | Film thickness |

| 012125 | IDA electrode (Au) | 10 | 5 | 2 | 65 | 90 nm ∗ |

| 012126 | IDA electrode (Pt) | 10 | 5 | 2 | 65 | 90 nm ∗ |

| 012127 | IDA electrode (Carbon) | 10 | 5 | 2 | 65 | 1.2 +/- 0.1 µm |

| 012128 | IDA electrode (ITO) | 10 | 5 | 2 | 65 | 100 +/- 20 nm |

| 012129 | IDA electrode (Au) | 3 | 3 | 2 | 65 | 90 nm ∗ |

| 012130 | IDA electrode (Pt) | 3 | 3 | 2 | 65 | 90 nm ∗ |

| 012257 | IDA electrode (Au) | 2 | 2 | 2 | 65 | 90 nm ∗ |

| 012258 | IDA electrode (Pt) | 2 | 2 | 2 | 65 | 90 nm ∗ |

| w/o passivation membrane | ||||||

| 012259 | IDA electrode (Au) without passivation membrane | 10 | 5 | 2.5 | 65 | 90 nm ∗ |

| 012262 | IDA electrode (Pt) without passivation membrane | 10 | 5 | 2.5 | 65 | 90 nm ∗ |

| 012266 | IDA electrode (Carbon) without passivation membrane | 10 | 5 | 2.5 | 65 | 1.2 +/- 0.1 µm |

| 012265 | IDA electrode (ITO) without passivation membrane | 10 | 5 | 2.5 | 65 | 100 +/- 20 nm |

| 012260 | IDA electrode (Au) without passivation membrane | 3 | 3 | 2.5 | 65 | 90 nm ∗ |

| 012263 | IDA electrode (Pt) without passivation membrane | 3 | 3 | 2.5 | 65 | 90 nm ∗ |

| 012261 | IDA electrode (Au) without passivation membrane | 2 | 2 | 2.5 | 65 | 90 nm ∗ |

| 012264 | IDA electrode (Pt) without passivation membrane | 2 | 2 | 2.5 | 65 | 90 nm ∗ |

| OPTION | ||||||

| 011066 | Cable kit for IDA electrode | |||||

| 011464 | Ag/AgCl Ink for reference electrode (2.0 mL) | |||||

∗ For Au and Pt, the thickness of the titanium adhesive layer is about 10 nm, resulting in a total thickness of 100 nm.

For the high-sensitivity detection by redox cycle using IDA electrode, dual potentiostat is required.

In addition, CS-3A Cell stand to reduce the noise, and the coating of the reference electrode portion to have the stable reference potential, applying such as silver-silver chloride ink, are recommended.

The IDA electrode is a very sensitive product. Here, some advice for the preservation and handling of IDA electrode will be described.

After receiving the product, it is recommended to test the insulation between the working electrodes using a tester.

If long-term storage, put the electrode in the case. Store the case in clean space such as desiccator, away from heat and moisture.

Any defects in the appearance (ex: pinhole on lead area, burr of glass) without any influence to the measurement, are not covered under warranty.

Experimental performance of the IDA electrode, with a small width (3 µm and 2 µm) is compared with the 10 um width IDA electrode.

Also, the collection efficiency was compared for the three types of the IDA electrodes.More fine IDA (Pt/Au) Electrode has been developed. Its 3 µm pitch working electrodes significantly increase redox cycle and allow researchers to perform ultra-sensitive measurement.

More fine IDA (Pt/Au) Electrode has been developed. Its 3 µm pitch working electrodes significantly increase redox cycle and allow researchers to perform ultra-sensitive measurement.

IDA Au (3 µm) IDA Pt (3 µm)

We recommend to apply Ag/AgCl ink to a reference electrode in order to stabilize potential of the electrode.

|

A CV curve obtained by 3 µm IDA Electrode Au [A] mirrored that of 3 µm IDA Electrode Au [B], which means both of the IDA Electrodes were produced very accurately.

|

Fig. 2 - CV by Dual mode |

|

Fig. 3 & 4 - Comparison of 3 µm IDA Au with 10 µm by Dual Mode

For 3 µm electrode, the limiting current of ferrocene methanol by CV Dual mode was 8 times as much as of the peak current by Single mode, while this ratio for 10 µm electrode was about 4. This means large increase of the redox cycle.

|

Fig. 5 - Capture Efficiency |

Figure 5 shows a result of LSV Dual mode measurement. Its collection efficiency was proved to be 96.4% by our calculation from limiting current of Collector electrodes and Generator electrodes.

|

Besides CV and LSV electrochemical techniques, our IDA electrode is available for various electrochemical measuring techniques such as chronoamperometry, normal pulse voltammetry, differential pulse voltammetry etc.

Researchers can obtain more insights by using IDA electrodes.

More fine IDA (Pt/Au) Electrode has been developed. Its 2 µm pitch working electrodes significantly increase redox cycle and allow researchers to perform high-ultra-sensitive measurement.

A CV curve obtained by 2 µm IDA Electrode Au.

Compared with IDA Au 10 µm and 3 µm, the capture efficiency of the 2 µm is higher, 93% for 10 µm and 95% for 3 µm.

For 2 µm electrode, the limiting current of ferrocene methanol by CV Dual mode was 11 times as much as of the peak current by Single mode, while this ratio for 10 µm and 3 µm electrode were about 4 and 7.5, respectively. This means large increase of the redox cycle.